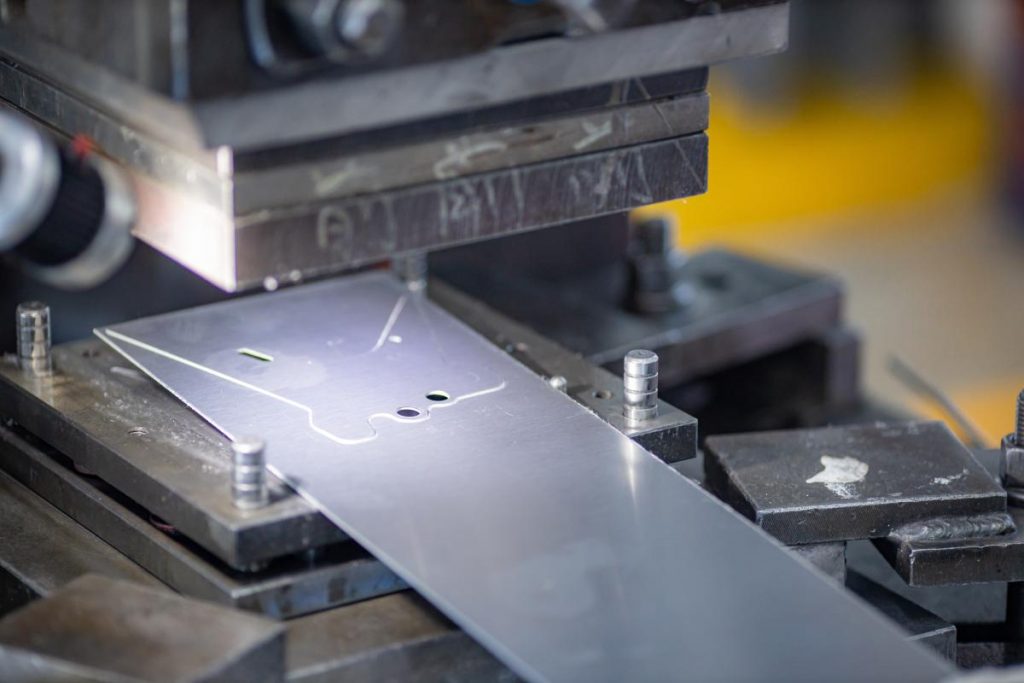

Sheet Metal Pressings - The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. Metal pressing, or stamping, encompasses a variety of techniques to shape metal sheets into desired forms, catering to diverse industrial. The metal is fed into a press, where.

The metal is fed into a press, where. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Metal pressing, or stamping, encompasses a variety of techniques to shape metal sheets into desired forms, catering to diverse industrial. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles.

Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. The metal is fed into a press, where. Metal pressing, or stamping, encompasses a variety of techniques to shape metal sheets into desired forms, catering to diverse industrial. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die.

Roller Die Can Press Brake Sheet Metal Roller Die

The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into.

Homemade Sheet Metal Pressing Tool Sheet Metal Press Door Decor

The metal is fed into a press, where. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. Metal pressing, or stamping, encompasses a variety of techniques to shape metal sheets into desired forms, catering to diverse industrial. The process of turning.

CostEffective Precision Sheet Metal Fabrication Process

Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or.

Proses Stamping dalam Pengolahan Sheet Metal KMI

The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Metal pressing, or stamping, encompasses a variety of techniques to shape metal sheets into desired forms, catering to diverse industrial. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping..

Sheet Metal Pressing Stamping Work at best price in Vadodara ID

Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The metal is fed into a press, where. Stamping (also known as pressing) is the process of placing flat sheet metal.

Machinery Manufacturing Steel Sheet Metal Pressing Stamping at ₹ 55 in

The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. The metal is fed into a press, where. Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles. Stamping (also known as pressing) is the process of.

Mild Steel Sheet Metal Pressing Stamping Work in Vadodara ID

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles. The process of turning sheets of metal into a useful part.

Sheet Metal / Pressing Parts Trueform Exports Pvt. Ltd.

Metal pressing, or stamping, encompasses a variety of techniques to shape metal sheets into desired forms, catering to diverse industrial. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. The metal is fed into a press, where. The metal stamping process.

Making a Sheet Metal Forming Press Die Test YouTube

The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. The metal is fed into a press, where. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Sheet metal pressing involves the use of hydraulic or mechanical presses to.

Forming on the modern punch press sheet metal fabrication’s Swiss army

The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. The metal is fed into a press, where. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Stamping (also known as pressing) is the process of placing flat sheet.

The Metal Is Fed Into A Press, Where.

The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Sheet metal pressing involves the use of hydraulic or mechanical presses to shape the metal sheet into specific forms or profiles. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die.